- Home

- Sponsors

- Forums

- Members ˅

- Resources ˅

- Files

- FAQ ˅

- Jobs

-

Webinars ˅

- Upcoming Food Safety Fridays

- Upcoming Hot Topics from Sponsors

- Recorded Food Safety Fridays

- Recorded Food Safety Essentials

- Recorded Hot Topics from Sponsors

- Food Safety Live 2013

- Food Safety Live 2014

- Food Safety Live 2015

- Food Safety Live 2016

- Food Safety Live 2017

- Food Safety Live 2018

- Food Safety Live 2019

- Food Safety Live 2020

- Food Safety Live 2021

- Training ˅

- Links

- Store ˅

- More

How Do We Determine the Control Limit in Unconventional Products?

Started by walabies, Apr 04 2008 09:07 AM

33 replies to this topic

#26

Posted 29 June 2008 - 04:38 PM

This limit isn't really suitable for using in our plant as the hygiene level wouldn't be up to par. Too stringent is bad for our daily job...

#27

Posted 30 June 2008 - 10:10 AM

Dear wallabies,

I certainly agree that there is no clear consensus on this subject.

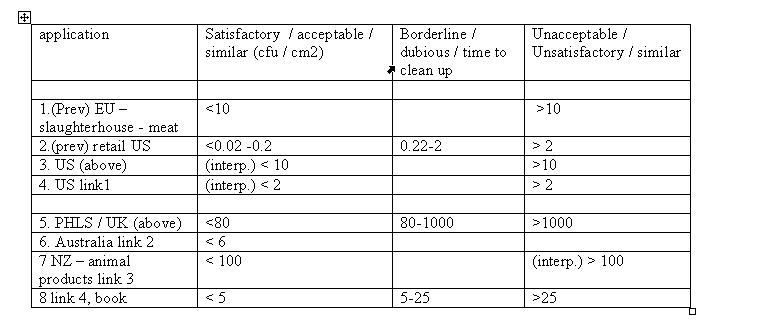

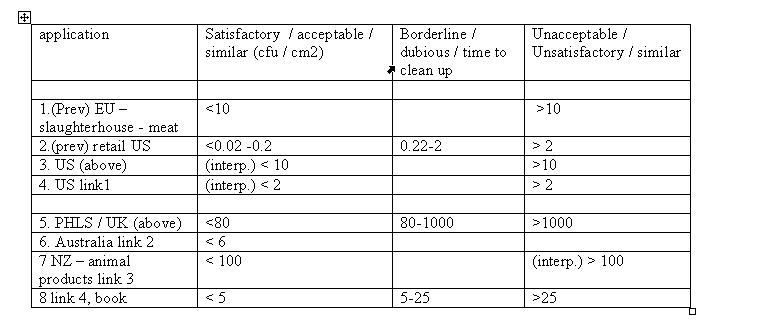

I found the topic rather interesting so I hv done a bit more searching and put together the data I prev. posted with some more I found to facilitate comparison.

A lot of this material is fairly old however I saw one recent detailed official survey in UK (operational swabbing of chopping boards / worktop surfaces) so I extracted 2 sections (opening / closing) which seemed interesting -

food_prep_surfaces__2006_.pdf 282.21KB

2437 downloads

food_prep_surfaces__2006_.pdf 282.21KB

2437 downloads

I hv tabulated the data seen with a few personal language adjustments / interpretations, please consult original references for accuracy -

Obviously substantial variations. Similar differences can also be seen if one compares micro. guidelines so perhaps it's not so surprising but I hv to say the data surprised me. As noted in the text above, the specific product application is relevant but even so ….?

What values are you using at the moment wallabies ???

It is quite possible there are calculative errors in above so I hv added the raw data below, any amendments etc are welcome to be pointed out.

added -

The central question here is, (as per thread title ), what is the criterion for setting the limits? Interestingly, none of the links above seems to quantitatively explain the basis for their proposed values

), what is the criterion for setting the limits? Interestingly, none of the links above seems to quantitatively explain the basis for their proposed values  . Several make the comment that the nature of the production imposes a restriction on the achievable degree of cleanliness, eg this extract –

. Several make the comment that the nature of the production imposes a restriction on the achievable degree of cleanliness, eg this extract –

I can see that there may inevitably be a practical relationship as referred above but how to define any tolerable variation has not been discussed in the refs I have seen. The ATP methods seem more determined to analyse such variables but I hv little knowledge this route. (One link suggested that there is now a 60+% penetration in the US market for ATP technique with the possibility of it becoming a specific standard.)

I have also seen an opinion that “too” clean a production area may be a bad thing in a food factory since it faces the law of diminishing returns plus may promote the occurrence of pathogenic species.

Rgds / Charles.C

(link 1)

(link 2)

(Link 3)

(link 4) ( you will hv to google the book), extracted from a review of “yoghourt science and technology” / tamime and robinson (1999)

I certainly agree that there is no clear consensus on this subject.

I found the topic rather interesting so I hv done a bit more searching and put together the data I prev. posted with some more I found to facilitate comparison.

A lot of this material is fairly old however I saw one recent detailed official survey in UK (operational swabbing of chopping boards / worktop surfaces) so I extracted 2 sections (opening / closing) which seemed interesting -

The effectiveness of cleaning practices can be monitored and/or verified by environmental sampling. Under Commission Regulation (EC) No 2073/2005 on Microbiological Criteria for Foodstuffs (6) environmental sampling must be undertaken in:

i) premises producing RTE foods which may pose a risk of L. monocytogenes and

ii) premises producing dried infant formula or dried foods for special medical purposes intended for infants below 6 months which pose a risk of Enterobacter saklazakii (in these premises the processing environment and equipment should be sampled for Enterobacteriaceae).

In other premises, environmental sampling should be carried out as necessary. The Regulation does not specify criteria for the acceptable level of microorganisms on surfaces. Rather, environmental sampling should be used as a tool by FBOs (= food business operators) to ensure the foodstuffs under their control meet the relevant process hygiene and food safety criteria.

Very few guidelines have been published on the acceptable level of microorganisms on surfaces. The US Public Health Service recommends that cleaned and disinfected food service equipment should not exceed 10 viable microorganisms per cm2 (7). The Public Health Laboratory Service (PHLS) in the UK recommended guidelines for cleaned surfaces ready for use: less than 80cfu/cm2 is satisfactory, 80-1000 cfu/cm2 is borderline and over 1000 cfu/cm2 is unsatisfactory (8). In addition, a Local Authorities Co-ordinating Body on Food and Trading Standards (LACOTS)/PHLS study of cleaning standards and practices in food premises correlated samples (surface samples and cleaning cloths) having aerobic colony counts > 1000cfu/cm2 with premises that did not have adequate food hygiene training, hazard analysis, cleaning schedules or cleaning records in place (9).

……..

Few standards have been published on the acceptable level of microorganisms on food preparation surfaces. This is because many factors (including the level of microorganisms on food, the availability of nutrients, the presence of preservatives and the environmental temperature) influence the microbial surface population prior to cleaning and the design and performance of the sanitation programme will determine the levels after cleaning. As these factors differ for every establishment, a common standard is hard to set (5). However, as a guideline ACC counts _ 1000 cfu/cm2 appear to be a suitable cut-off point between acceptable and unacceptable surface hygiene for the food preparation surfaces examined in this survey (the applicability of this guideline to other types of food preparation surfaces cannot be assumed). Where appropriate, swabbing can be used in conjunction with other inspection activities to draw a complete picture of the hygiene of a food premises.

food_prep_surfaces__2006_.pdf 282.21KB

2437 downloads

food_prep_surfaces__2006_.pdf 282.21KB

2437 downloadsI hv tabulated the data seen with a few personal language adjustments / interpretations, please consult original references for accuracy -

Obviously substantial variations. Similar differences can also be seen if one compares micro. guidelines so perhaps it's not so surprising but I hv to say the data surprised me. As noted in the text above, the specific product application is relevant but even so ….?

What values are you using at the moment wallabies ???

It is quite possible there are calculative errors in above so I hv added the raw data below, any amendments etc are welcome to be pointed out.

added -

The central question here is, (as per thread title

http://www.3m.com/in...q_swab/use1.pdfIn addition, processors may wonder about standards for acceptable counts in their environmental testing program. Adequate cleaning and sanitizing should be sufficient to keep counts low. The Compendium of Methods references the U.S. Public Health Service recommendation that “adequately cleaned and sanitized food service equipment

have not more than 100 colonies per utensil”1 and also states, “Generally, the level of microorganisms should not exceed more than a few colonies per sampling site.”

Because counts may vary depending on the operation or type of product being processed, it is difficult to give a one-size-fits-all standard. What may be "normal" for one product or process may not be "normal" for another. For instance, an incoming area for food which comes directly from a farm field may have higher counts than an area containing a highly processed frozen food. Both count levels may be acceptable based on the expected microbial load of the food being processed.

I can see that there may inevitably be a practical relationship as referred above but how to define any tolerable variation has not been discussed in the refs I have seen. The ATP methods seem more determined to analyse such variables but I hv little knowledge this route. (One link suggested that there is now a 60+% penetration in the US market for ATP technique with the possibility of it becoming a specific standard.)

I have also seen an opinion that “too” clean a production area may be a bad thing in a food factory since it faces the law of diminishing returns plus may promote the occurrence of pathogenic species.

Rgds / Charles.C

(link 1)

The U.S. Public Health Service suggests that a sanitized surface must have less than 100 total aerobic organisms per 8 square inches of surface (e.g., cutting board, dish, tabletop, etc.) or 100 organisms per utensil (e.g., spoon) (190). This is an adequate standard that is used as a sanitation guideline in the Grade A Pasteurized Milk Ordinance (54).

http://www.hi-tm.com...t-5A.html#clean

(link 2)

Food Processors Surface Hygiene

A major component of the hygiene of a kitchen, processing line or food production plant is the control of the cleaning of equipment, storage tray, utensils and preparative benches. A simple inexpensive test provides a quantitative test with has a sensitivity down to 0.4 CFU/square centimetre. The Australian standard (AS 2997-1987) states that an acceptable limit to indicate satisfactory cleaning operations by this method is less than 6 CFU/square centimetre.

http://www.biotechla...u/services2.htm

(Link 3)

- 5.3.10.2 Performance Standards

a. Pre-operational:

For raw meat processing, microbiological loading of commercially clean food contact surfaces has been found over time to normally be <102cfu/cm2. One-off counts could be in the 102 to 103 cfu/cm2 range but would not be the norm.

b. During operations:

The microbiological condition of any food contact surface during operations, as measured by the mean log10 count of the indicator organism(s), should not exceed the expected mean log10 count of similar indicator organism(s) on product.

The numbers of micro-organisms on food surfaces throughout a processing day will be influenced by cleaning programmes, incoming microbial loads on the food and the opportunities for growth during production. The objective of this standard is to minimise contamination of foods through redistribution of micro-organisms from food surfaces.

http://www.nzfsa.gov...h-3/page-04.htm

(link 4) ( you will hv to google the book), extracted from a review of “yoghourt science and technology” / tamime and robinson (1999)

some suggested standards for plant in contact with foods prior to pasteurisation/heat treatment have been suggested by Harrigan and McCance(1976)

cfu / 100cm2 conclusion

500(coliforms <10) satisfactory

500 – 2500 dubious

>2500 (coliforms > 100) unsatisfactory

With improved cleaning regimes a total colony count of 200cfu/100cm2 would be expected nowadays and below 50cfu/100cm2 for any plant containing pasteurised products (Luck and Gavron 1990)

Kind Regards,

Charles.C

|

Thanked by 3 Members:

|

, ,

|

#28

Posted 02 July 2008 - 07:56 AM

Great work once again Charles.

Does anyone who has been involved with this discussion care to comment further on the research Charles has carried out?

Does anyone who has been involved with this discussion care to comment further on the research Charles has carried out?

Get FREE bitesize education with IFSQN webinar recordings.

Download this handy excel for desktop access to over 180 Food Safety Friday's webinar recordings.

https://www.ifsqn.com/fsf/Free%20Food%20Safety%20Videos.xlsx

Check out IFSQN’s extensive library of FREE food safety videos

https://www.ifsqn.com/food_safety_videos.html

|

Thanked by 1 Member:

|

|

#29

Posted 04 July 2008 - 06:46 AM

Dear Walabies,

Just a note re typical limits. From an analytical chemistry perspective it is very helpful to know these, as it allows the correct sample size to be used according to the sensitivity of the test method. (Not sure if this is applicable to micro testing).

Toni

Just a note re typical limits. From an analytical chemistry perspective it is very helpful to know these, as it allows the correct sample size to be used according to the sensitivity of the test method. (Not sure if this is applicable to micro testing).

Toni

#30

Posted 04 July 2008 - 02:42 PM

Hi Walabies,

Back to your original question, you might want to consider the chemical hazard of heavy metal as well.....

Back to your original question, you might want to consider the chemical hazard of heavy metal as well.....

#31

Posted 25 April 2013 - 01:04 AM

Dear walabies,

Assuming “non-dairy creamer” is the product involved, googling “microbiological specifications non-dairy creamer” offers a good selection of sets of micro.limits, eg http://www.smpfoodsu...yLac%20spec.htm (perhaps you’ve done this already ?) . Unfortunately, although helpful indicators, most of them are incomplete operationally since they hv no associated sampling plan. Al’s previous example illustrates a more satisfactory format.

added - a much less statistically correct but popular option IMEX is to do a rotating selection of products every X days using a small sample size with application of a denser / defined sampling plan in case of any failure of limits. After all, proper HACCP is supposed to reduce the necessity of frequent mic.testing [> verification step] which can also be very expensive / time consuming. However this option may forcibly depend on yr particular product / customer requirements etc.

Rgds / Charles.C

Dear Charles, I found Salmonella (25 gram): absent 25 gram, E.coli 0.1 gram. What is that mean. I interpreted this as they both not supposed to be found in product. is that right? or maybe there is reading limit that you could please to clear it. sorry for my grammar. thanks.

#32

Posted 25 April 2013 - 01:40 AM

Dear Charles, I found Salmonella (25 gram): absent 25 gram, E.coli 0.1 gram. What is that mean. I interpreted this as they both not supposed to be found in product. is that right? or maybe there is reading limit that you could please to clear it. sorry for my grammar. thanks.

Dear arctefax,

I assume yr quote is from a product specification.

Some specification statements have defined regulatory meanings depending on factors like specific food, location.

The Salmonella quote often indicates that “testing” should not detect Salmonella spp. in a sample of 25grams. There is a zero-tolerance policy for Salmonella in many foods.

The E.coli quote is ambiguous IMO. One interpretation might be that generic E.coli should not be detected by "testing" a sample size of 10g. Others are possible.

Rgds / Charles.C

Kind Regards,

Charles.C

#33

Posted 05 June 2017 - 11:00 PM

It's not milk based, but I absolutely would treat this product like a dried milk product. It has many of the same characteristics like pH, water activity, and sugar content. It seems like a pretty good standard to apply to the product (unless you have trouble meeting it for some reason). Just like I enjoy the packaging standards for milk for beverages in general.

Looking at NACMCF's most recent recommend FG microbial specs for dried dairy products:

APC: <10,000

Coliform: <10

Salmonella: Negative

Non-routine tests recommended are environmental salmonella and listeria in zones 2-3, and EB testing in product. Other similiar products would be things like Spices, which recommend APC <100,000 and salmonella negative as routine.

I see a lot of higher coliform specs thrown around on this forum....if it's a product subject to some kind of kill step I generally would expect to find very few to no coliforms in general and I would be concerned in my facility if I routinely saw high counts there.

Austin Bouck

Owner/Consultant at Fur, Farm, and Fork.

Consulting for companies needing effective, lean food safety systems and solutions.

Subscribe to the blog at furfarmandfork.com for food safety research, insights, and analysis.

Owner/Consultant at Fur, Farm, and Fork.

Consulting for companies needing effective, lean food safety systems and solutions.

Subscribe to the blog at furfarmandfork.com for food safety research, insights, and analysis.

|

Thanked by 2 Members:

|

,

|

#34

Posted 05 June 2017 - 11:07 PM

Hi 3F,

I think you've answered a 9-year old OP.

Interesting nonetheless. Thks. ![]()

Kind Regards,

Charles.C

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users